-

Notifications

You must be signed in to change notification settings - Fork 3

Home

Our long term goal is to is to build a modular platform, not just a printer. Think of it as an ecosystem of parts that can be arranged in different configurations and adapted for unique applications.

- All Metal Parts

- Upgrades

- Customizable

- Modular

- Scalable to a larger format

- Linear Rails

- BOM utilizes standard and available printer parts people already have so they can convert their printer into a SolidCore

- Easily add an enclosure

https://3ddistributed.com/product/corexy-mechanism/

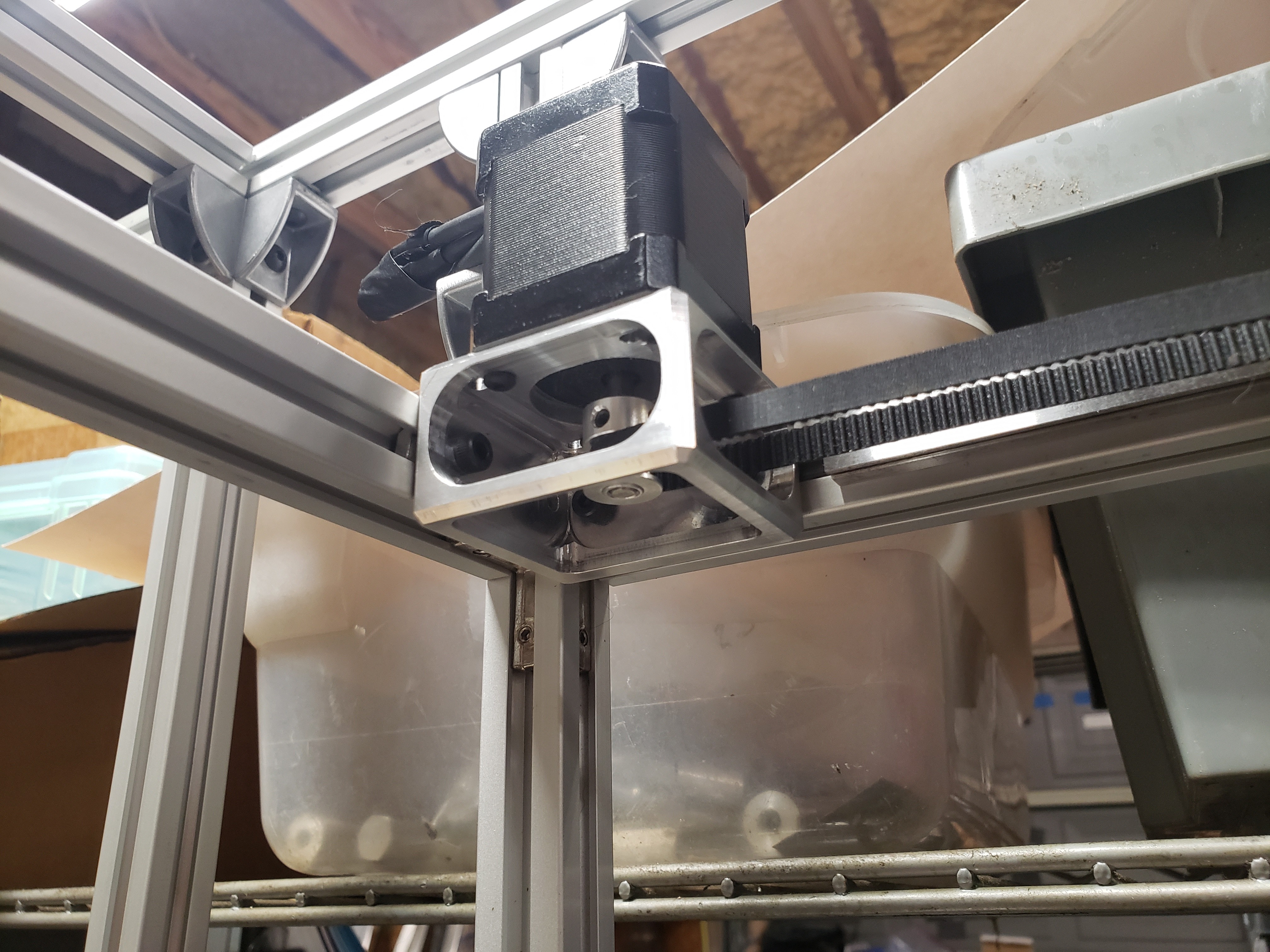

We’ll probably make some changes such as reorienting the the y-axis linear rail into a vertical position similar to the RailCore, redesigning the carriages and motor/belt mounting plates where the z-axis motors are placed on the bottom of the machine. I’m also considering making the carriage components and rail support one piece similar to the latest update on E3D’s Tool Changing printer.

While the SolidCore 3D Printer design had a lot of influence from the Railcore's design, which also has the "x" shape belt path that some say “serves no purpose.” True, but you see the quality prints that the Railcore community is putting out. The print quality of the RailCore is AMAZING! Although the belts don't have to cross if the pulleys are at different z-levels. I originally thought that the difference between the hbot core xy design was that the corexy belts crossing segment.

The corexy kinematics is a complex motion system with dedicated stepper motors for each axis. The X and Y motors move together or opposite of each other to move the carriage from left to right or towards or away . If you were to move just one motor you would see the print head move diagonal.. If the two motors move opposite of each other the print head will move along the X-axis, If the two motors move in the same direction the carriage will move along the Y-axis. Read More https://3ddistributed.com/corexy-3d-printer/corexy-kinematics

- Both Motors Move Clockwise >> Carriage Moves Left

- Both Motors Move Counter Clockwise>> Carriage Moves Right

- Both Motors Move Opposite of Each Other>> Carriage Moves Toward & Away

- One Motor Moves>> Carriage Moves Diagonal

Offsetting the stepper motors with stacked belt path pulleys may give the belts a clean run and simplify belt alignment. A printer's motors can be offset at different heights so that the belt routing runs a straight belt path and don't have to be twisted. But this belt routing path would also mean that on one side of the gantry the belt would have the teeth on the side of the idler wheel which wouldn't run as smooth and could lead to artifacts within printed parts. We already designed and built the SolidCore with the crossed belt path so we're going to stick with it for now. Later on after many performance tests I'll try out some other design configurations to test out any changes.

I'll update the files when finished but there’s still a lot of work to be done. www.3ddistributed.com